The Ultimate Guide to Heat Shrink Tubing Label Makers

In the modern world of business, the importance of clear, durable labeling cannot be overstated. If you are involved in the fields of printing services or electronics, having an efficient way to create labels that can withstand extreme conditions is crucial. This is where heat shrink tubing label makers come into play. With their unique capabilities, these tools can enhance your labeling process, making it more effective and efficient.

Understanding Heat Shrink Tubing

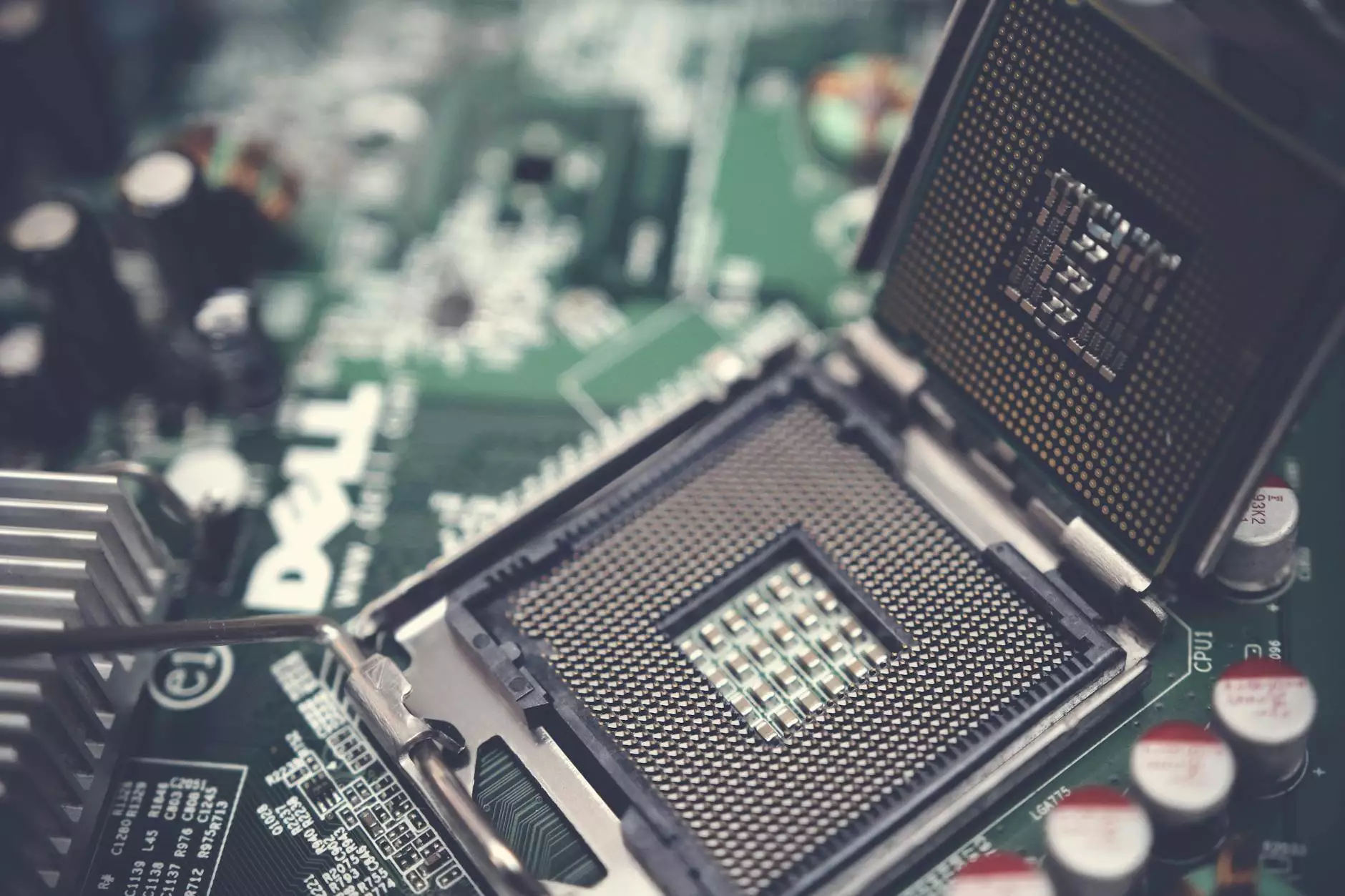

Before diving into the specifics of heat shrink tubing label makers, it is essential to understand what heat shrink tubing is. Heat shrink tubing is a type of plastic tubing that shrinks in diameter as it is exposed to heat. When applied to wires, cables, or components, it provides a tight, protective seal that can protect against moisture, dust, and mechanical damage.

Applications of Heat Shrink Tubing

Heat shrink tubing is used in a variety of applications, including:

- Electrical Insulation

- Cable Management

- Color Coding

- Protecting Connectors

- Repairing Damaged Cables

The Role of Heat Shrink Tubing Label Makers

Heat shrink tubing label makers are specialized devices designed to print labels directly onto heat shrink tubing. These label makers ensure that the text on the tubing is not only clear but also permanent, capable of withstanding harsh conditions.

Key Features of Heat Shrink Tubing Label Makers

When selecting a heat shrink tubing label maker, it is vital to consider its features, which can include:

- Customizable Labeling: Create a wide range of custom labels including sizes, fonts, and colors.

- Durability: Labels are resistant to heat, chemicals, and abrasion, ensuring they last

- Speed: Quickly produce labels to keep up with business demands.

- User-friendly Interface: Many models come with intuitive controls that ease the labeling process.

- Connectivity Options: Modern devices often include connectivity features for easier design and printing.

Benefits of Using Heat Shrink Tubing Label Makers

The advantages of utilizing a heat shrink tubing label maker are numerous, making them an indispensable tool for any business that requires robust labeling solutions.

1. Enhanced Visibility and Readability

Labels created using heat shrink tubing label makers are not only easier to read but also stand out against various backdrops. This is particularly important in electronic environments where clear indications of wires and connections are necessary.

2. Improved Organization

Using these label makers can help maintain a more organized workspace. By labeling cables and components accurately, you can streamline the workflow and reduce the chances of errors during assembly or repairs.

3. Cost-Effectiveness

Investing in a heat shrink tubing label maker can lead to substantial cost savings in the long run. By reducing waste associated with mislabeling and providing reliable, long-lasting labels, these devices can positively impact your bottom line.

4. Safety Compliance

Many industries are governed by strict safety regulations. Utilizing a heat shrink tubing label maker allows you to comply with these regulations by providing clear labeling that informs employees and customers about potential hazards.

5. Versatile Applications

From electrical installations to industrial settings, heat shrink tubing label makers can be utilized in a variety of fields, including:

- Telecommunications

- Aerospace

- Automotive

- Home Improvement

- Medical Equipment

Choosing the Right Heat Shrink Tubing Label Maker

When searching for the perfect heat shrink tubing label maker, it is important to consider the following factors:

1. Compatibility with Tubing Sizes

Ensure that the label maker can accommodate the sizes of heat shrink tubing you frequently use in your business.

2. Printing Technology

Some label makers use thermal transfer printing, while others may use direct thermal printing. Understanding the differences can help you select the best option for your needs.

3. Software Integration

Select a model that integrates well with software platforms you already use for designing or database management.

4. Portability

If you need to print labels on-the-go, consider a portable heat shrink tubing label maker that can easily be transported between job sites.

Tips for Efficient Labeling with Heat Shrink Tubing Label Makers

To maximize the potential of your heat shrink tubing label maker, here are some valuable tips:

- Regular Maintenance: Keep your label maker in good working condition with regular cleaning and maintenance.

- Test Print: Always conduct a test print to ensure that the labels are clear and correctly formatted before processing a batch.

- Keep Labels Organized: Use a system for organizing and storing labels according to your process requirements.

- Stay Up-to-Date: Keep abreast of new features and updates for your model to ensure you're utilizing its full potential.

Conclusion

In conclusion, the use of a heat shrink tubing label maker can significantly enhance your business operations in the realms of printing services and electronics. By ensuring that your labels are durable, readable, and efficient, you can improve organization, safety, and productivity in your workplace.

Considering the state-of-the-art features available today, investing in a high-quality heat shrink tubing label maker will yield dividends in various aspects of your business. Embrace the future of labeling and make your processes more effective with innovative labeling solutions that stand the test of time.