Plastic Prototyping Service

Introduction

Deep Mould, a leading company in the metal fabrication industry, offers a comprehensive plastic prototyping service. With our strong expertise as metal fabricators, we have extended our capabilities to provide exceptional prototyping solutions, ensuring that you receive high-quality products that perfectly meet your requirements.

Why Choose Deep Mould?

When it comes to plastic prototyping, Deep Mould stands out from the competition. Here are the key reasons why you should choose our services:

1. Industry Experience

With years of experience in metal fabrication and prototyping, our team at Deep Mould possesses a deep understanding of the industry. We have successfully served numerous clients from various sectors, showcasing our ability to adapt and deliver outstanding solutions.

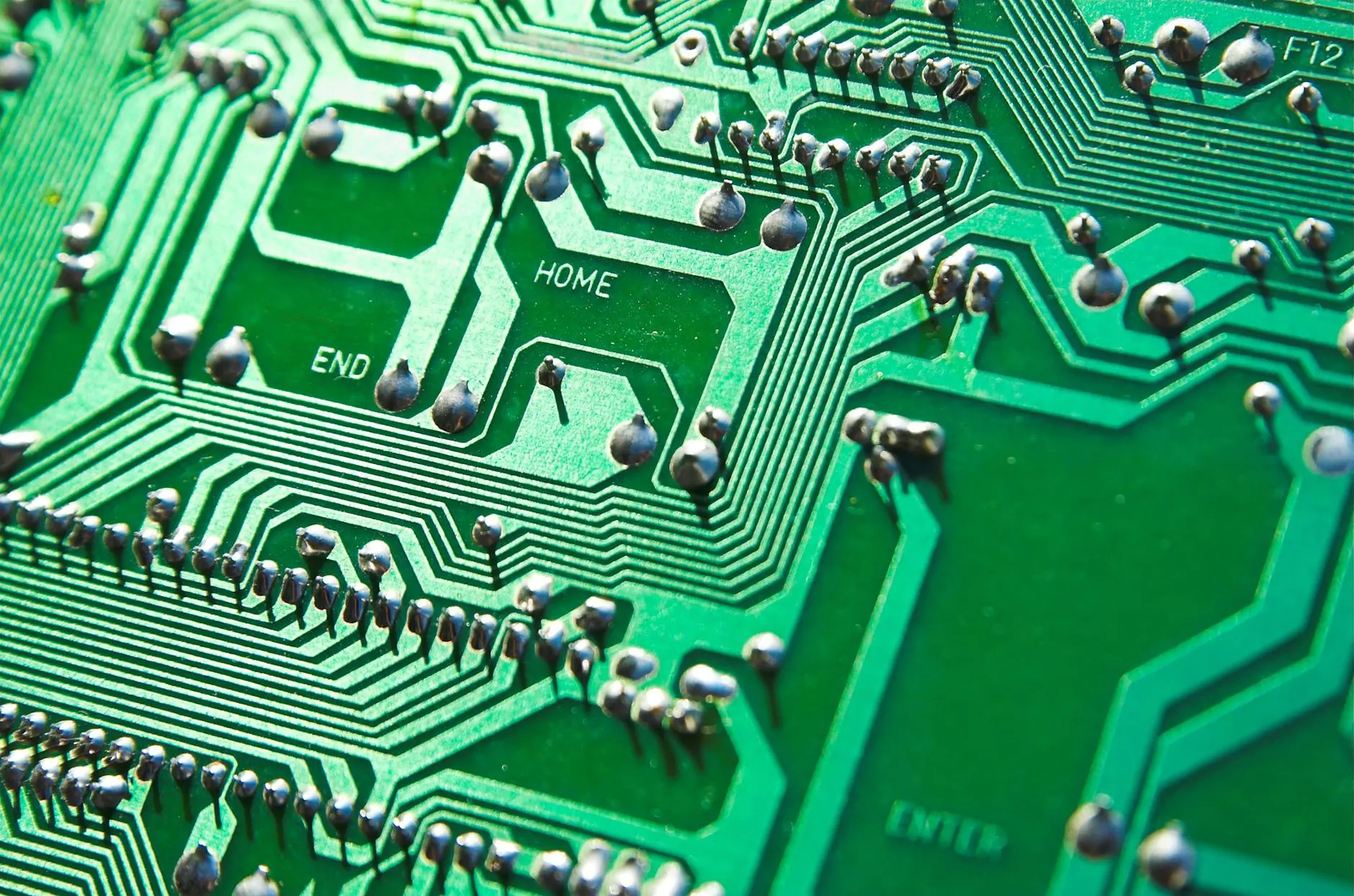

2. Advanced Technology

To ensure precision and efficiency in our plastic prototyping service, we utilize state-of-the-art technology and cutting-edge equipment. Our well-maintained facilities allow us to create intricate prototypes with accuracy, meeting the highest industry standards.

3. Skilled Team

Our team of highly skilled professionals is dedicated to providing top-notch plastic prototyping solutions. With their expertise and attention to detail, we can guarantee exceptional results and deliver prototypes that exceed your expectations.

4. Tailored Solutions

At Deep Mould, we understand that every client has unique requirements. Therefore, we offer tailored solutions for your plastic prototyping needs. Our team works closely with you to ensure that your vision is translated into the final product, with meticulous attention to detail throughout the process.

Our Plastic Prototyping Process

Deep Mould follows a well-defined process to deliver high-quality plastic prototypes. Our process includes:

1. Design Consultation

Our experienced team collaborates with you to understand your project's specifications. We take into account your design requirements, functionality goals, and production needs to develop an optimal prototyping strategy.

2. Material Selection

Choosing the right material is crucial for successful plastic prototyping. We guide you in selecting the most suitable plastics based on your project's requirements, considering factors such as strength, durability, and surface finish.

3. Prototyping Development

Once the design and materials are finalized, our skilled fabricators utilize advanced techniques to bring your concept to life. We use computer-aided design (CAD) software and 3D printing technologies to create precise prototypes that accurately represent your product.

4. Testing and Refinement

Before the finalization of the prototype, we conduct thorough testing to ensure its functionality, durability, and overall performance. If any improvements are needed, we refine the design and repeat the testing process until we achieve optimal results.

5. Final Prototype Delivery

Once the prototype meets your requirements and passes our rigorous quality checks, we deliver it to you promptly. Our goal is to provide you with a flawless prototype that seamlessly integrates into your production process.

The Benefits of Plastic Prototyping

Plastic prototyping offers several advantages for businesses. Here are some key benefits:

1. Rapid Turnaround

With the help of plastic prototyping, you can significantly reduce the time required for product development. Rapid prototyping techniques allow for quick iterations and modifications, accelerating the overall manufacturing process.

2. Cost Efficiency

By creating plastic prototypes, you can identify and rectify design flaws or functionality issues early in the production cycle. This saves both time and money, as manufacturing errors can be costly to fix once the product reaches mass production.

3. Design Validation

Plastic prototypes enable you to visualize and validate your product designs before investing in mass production. This validation step allows for feedback and early user testing, ensuring that your final product meets customer expectations.

4. Improved Collaboration

Creating plastic prototypes facilitates effective collaboration between teams involved in product development. It allows designers, engineers, and stakeholders to interact, provide feedback, and make necessary adjustments to enhance the product's performance and aesthetics.

Conclusion

Deep Mould's plastic prototyping service is tailored to meet your specific needs as a business. With our extensive industry experience, advanced technology, skilled team, and commitment to delivering exceptional results, we are your ideal partner for metal fabrication and plastic prototyping requirements.